A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

Design for Solar Entrance houses, Apeldoorn (Lars Courage Architects).

The majority of our buildings have a permanent built-in capacity for the storage of heat and cold. A building is either thermally heavy or thermally light. This means that thermal comfort at minimal energy consumption is not feasible throughout the year. After all, a thermally heavyweight building needs more energy in both summer and winter, but a thermally lightweight building needs more energy in spring and autumn.

Eindhoven University of Technology is researching the options of combining the benefits of both thermally heavyweight and lightweight buildings: hybrid adaptive thermal energy storage (HATS).

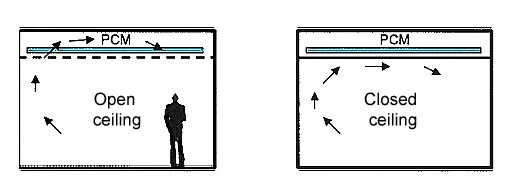

Hybrid adaptive thermal energy storage (HATS) is the subject of research at Eindhoven University of Technology, in collaboration with the Material Innovations Institute (M2i) and Tata Steel. HATS represents the potential of enabling the thermal mass of a building to be changed to suit the season or a changing climate. To enable this PCMs are fitted in a partially open suspended ceiling.

HATS: modification of the thermal mass by using PCMs in the ceiling.

Approach

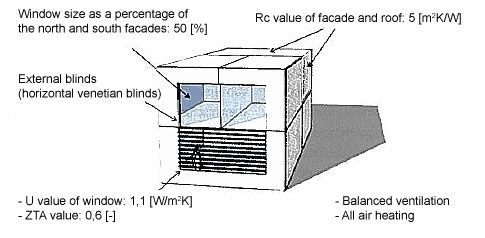

Courage Architects' design for the Sun Entrance houses in Apeldoorn is a research project. These homes are currently being built. The lightweight frames are made of steel. The characteristic structural properties of the houses are shown in the figure below:

Physical properties of the houses in the HATS trial

During the investigation the energy use of the house over a year is being simulated. Two occupancy profiles are being observed:

The simulation of the energy use is carried out at low thermal mass (5 kg/m2), high thermal mass (100 kg/m2) and an adjustable thermal mass (HATS).

The performances of the three options are expressed as:

Results

The energy performance of the three heating demand options and weighted temperature excess hours are shown in the table. The figures between brackets illustrate the percentage deviation of the energy consumption.

|

Demand for heat |

Weighted temperature excess hours |

|||||||||

| Low thermal mass (5 kg/m2) |

High thermal mass (100 kg/m2) |

Simplified HATS model |

Low thermal mass (5 kg/m2) |

High thermal mass (100 kg/m2) |

Simplified HATS model |

|||||

| Evening | 15.9 | (+7%) | 18.5 | (+25%) | 14.8 | 699 | (+10325%) | 7 | (+0%) | 7 |

| Day & evening | 25.0 | (+27%) | 20.9 | (+6%) | 19.7 | 2850 | (+1358%) | 196 | (+0%) | 196 |

1 TVVL magazine 02-2011: Hybrid adaptive thermal energy storage; P. Hoes (M2I and TU/e), M. Trcka (TU/e), Prof J.L.M. Hensen (TU/e), B. Hoekstra Bonnema (Tata Steel Construction Centre).

The table shows that when HATS is used, the demand for heat can be reduced by up to 27%. The number of weighted temperature excess hours is minimal.

Sensitivity Analysis

Next the physical parameters that had the most influence on the demand for heat and weighted temperature excess hours were investigated.

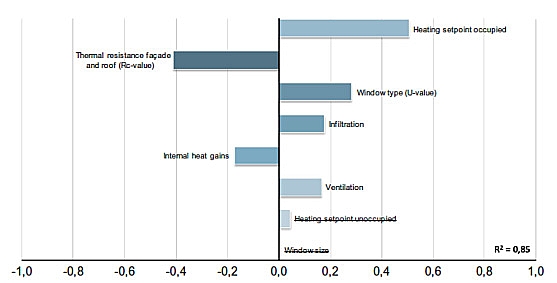

The heat setting temperature and the insulation level of the shell are the main factors that determine the demand for heat:

Influence of various parameters on the demand for heat. The longer the bar, the greater the influence.2

2 Investigation of the potential of a novel low-energy house concept with hybrid adaptable thermal storage, P. Hoes (M2I and TU/e),

M. Trcka (TU/e), Prof J.L.M. Hensen (TU/e), B. Hoekstra Bonnema (Tatasteel Construction Centre)

Energy and Management 52, Elsevier.

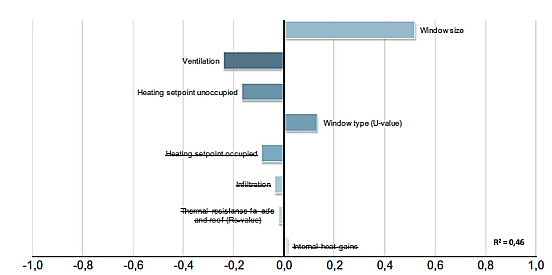

For the weighted temperature excess method hours, the window size and ventilation are the most influential:

Influence of different parameters on the weighted temperature excess method hours. The longer the bar, the greater the influence.2

In a new simulation, the influential parameters were varied between minimum and maximum. Then from this parameter study two variants for which HATS was the most beneficial were extracted. The difference between variant 1 and variant 2 was the insulation. For variant 1 this was: 3 m2K/W and for variant 2: 8 m2K/W. The table below shows the results:

|

Demand for heat |

Weighted temperature excess hours |

|||||||||

| Low thermal mass (5 kg/m2) |

High thermal mass (100 kg/m2) |

Simplified HATS model |

Low thermal mass (5 kg/m2) |

High thermal mass (100 kg/m2) |

Simplified HATS model |

|||||

| Variant 1 | 14.9 | (+9%) | 17.4 | (+35%) | 12.9 | 2095 | (+1295%) | 149 | (+1%) | 148 |

| Variant 2 | 8.5 | (+15%) | 9.7 | (+31%) | 7.4 | 1844 | (+1076%) | 157 | (+0%) | 157 |

The table shows that with the use of HATS the heat demand can be reduced by up to 35%, in comparison with a high thermal mass. The number of weighted temperature excess method hours can be reduced by a maximum of 1.295% can be reduced, in comparison to a low thermal mass.

Conclusions

These results apply generally to buildings where there are often no people present for long periods, e.g. houses (the residents are at work during the day), offices (the personnel are at home in the evenings) and hotels (the guests are exploring their holiday destination during the day). These buildings often have to be heated quite substantially from a low to a high (residence) temperature.

The results will be different for buildings with continuous occupation and demand for heat, e.g. hospitals, cell complexes, factories producing 24 hours per day.