A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

Villa Jansen, Rotterdam (Designed by Erick van Egeraat)

In both the EAF steelmaking process and the BF process (see routes for steel production), CO2 emissions can be reduced by 10-15%. The steel industry has made major investments in this area. Tata Steel, IJmuiden is currently developing a new process for CO2 reduction in the blast furnace. The objective of this project (ULCOS) is a decrease of 50%. In the first project phase 200 (variant) production routes have been investigated for emissions, technological development and (future) implementation options. Four promising technologies have emerged from the survey:

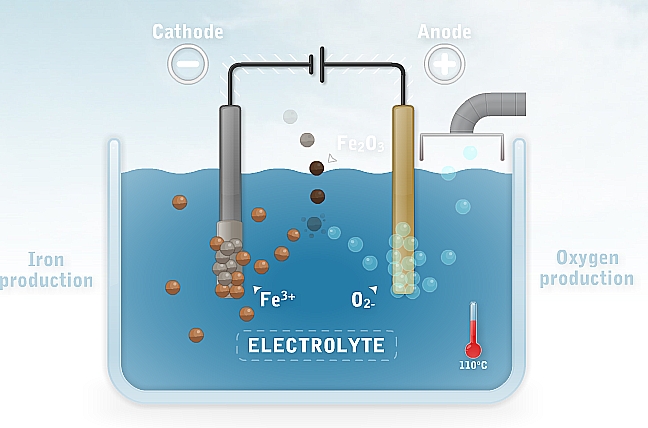

Iron ore electrolysis: electrolysis of iron from iron ore emits no CO2

Top gas recycling and HIsarna appear the most promising for Ultra Low CO2 Steelmaking. In 2010 ULCOS carried out phase two: a first step towards scaling up the technology to an industrial production process. To do this a 'small' blast furnace was built in IJmuiden in 2011 having a capacity of 1 million tons of steel.

More information about ULCOS is available in the presentation that was given at the National Steel Construction Day (Nationale Staalbouwdag) in 2010. This is available from the download section.