A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

There are now a number of ranges of PCMs as well as construction products incorporating PCMs ready for use in buildings available in the Netherlands. Some suitable products and semi-manufactured products for the building industry are:

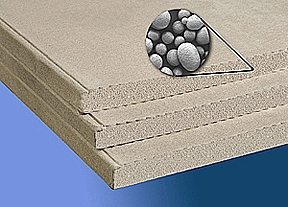

Micronal is a semi-manufactured product from BASF, which consists of paraffin beads encapsulated in a polymer. The microcapsules are about 5 microns in diameter and can be incorporated in plaster, plasterboard and concrete. Micronal has a heat of fusion of 100 kJ/kg. The melting temperature is 23°C.

Maxit Clima is also a BASF product and an example of a construction product incorporating a PCM. It is a spray plaster in which Micronal is incorporated. These paraffin beads increase the thermal mass of the plaster. A wall with 3 cm Maxit Clima possesses the same thermal mass as an 8 cm thick concrete wall or a 13 cm plasterboard wall without PCM.

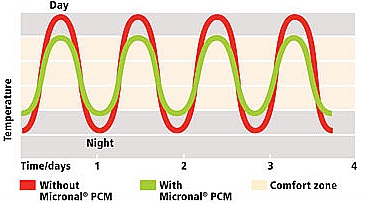

ThermalCore is a plasterboard containing Micronal. National Gypsum makes the board mainly for use in walls in housing. The PCM in the board flattens out the temperature peaks during the day/night cycle, thus maintaining the living room in the comfort zone.

The influence of PCM in a ThermalCore plasterboard wall on the temperature gradient in a living room

Like Micronal, Thermusol is a semi-manufactured product. The PCM in the beads is not paraffin wax, but in this case it is a salt hydrate. The manufacturer/supplier, Salca, Ootmarsum in the Netherlands, offers three types of Thermusol as part of the standard product range: HD28, HD32 and HD60 with melting temperatures of 28, 32 and 60°C. The heat of fusion is resp.110, 150 and 160 kJ/kg. On request Thermusol can be produced with a melting temperature in the range 5-90°C.

Salca itself has used Thermusol in two complete products for the construction industry:

K-Block: a mat of two layers of fibrous material for absorbing (excess) heat. This can be laid loose on a system ceiling or against the inside of a roof. www.salcabv.nl

Thermupod: pads for increasing the heat storage capacity of a buffer vessel for example. www.salcabv.nl

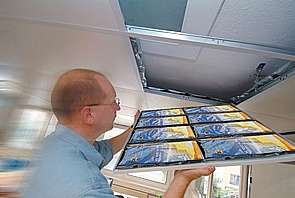

Autarkis climate ceilings consist of polypropylene panels encapsulating PCMs. The melting temperature of the PCM is 21°C. The panels are mounted as 'islands' on a fixed ceiling. The PCM islands then regulate the cooling, heating and ventilation of the room. www.autarkis.nl

Climate Floors from Autarkis, based in Almere in the Netherlands, are also PCM panels. 50% of the floor surface can be fitted with these panels, saving 50% on the heat absorbing capacity of the floor structure. www.autarkis.nl

Energain is a wall panel from Dupont. It is finished with an aluminium laminate. The core consists of copolymers with a paraffin PCM. The melting temperature is 22°C and the solidification temperature 18°C. The specific heat of melting is 515 kJ/m2.The panel is relatively thin (5.26 mm) combined with a low weight (4.5 kg/m2).

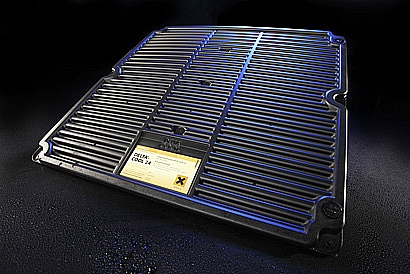

Delta Cool 24 has been developed by Cosella-Dörken to provide increased thermal comfort in office spaces, especially for (extra) cooling at high internal heat loads, as often occur in offices. The elements - 610 x 610 x 71 mm - are made of polymers and PCMs. The melting temperature is 22-28°C and the solidification temperature is 22°C. The specific heat of melting is 158 kJ/kg. That equates to a cooling capacity of up to 44 Wh/kg.